The conductor ensures a proper fit in the crimp barrel, playing a crucial role in ensuring a secure and reliable electrical connection. This article delves into the types of conductors, crimp barrels, and crimping techniques used in electrical wiring, emphasizing the importance of choosing the correct components and following proper crimping procedures.

Understanding the factors that affect the conductivity of conductors, the purpose and types of crimp barrels, and the operation of crimping tools is essential for creating strong and durable electrical connections. This article provides a comprehensive overview of these aspects, guiding readers through the intricacies of electrical wiring.

Conducting the Current: The Role of Conductors in Electrical Connections: The Conductor Ensures A Proper Fit In The Crimp Barrel

In the realm of electrical systems, conductors play a crucial role in ensuring the seamless flow of electricity. These materials serve as the pathways through which electrons travel, forming the backbone of electrical circuits and devices.

Types of Conductors

- Metals:Copper, aluminum, and silver are commonly used metals for conductors due to their excellent conductivity and malleability.

- Alloys:Alloys such as brass and bronze enhance the mechanical strength of conductors while maintaining good conductivity.

- Graphite:A form of carbon, graphite finds application in high-temperature and corrosive environments due to its chemical inertness.

- Semiconductors:Materials like silicon and germanium exhibit varying conductivity depending on external factors, making them essential for electronic devices.

Conductivity and Factors Affecting It

The conductivity of a conductor is a measure of its ability to facilitate electron flow. Factors influencing conductivity include:

- Material composition:The atomic structure and purity of the conductor material determine its inherent conductivity.

- Temperature:Conductivity generally decreases with increasing temperature due to increased electron scattering.

- Physical defects:Imperfections and impurities in the conductor can hinder electron movement, reducing conductivity.

- Magnetic fields:External magnetic fields can induce eddy currents in conductors, which oppose electron flow and lower conductivity.

Crimp Barrels: Securing Electrical Connections

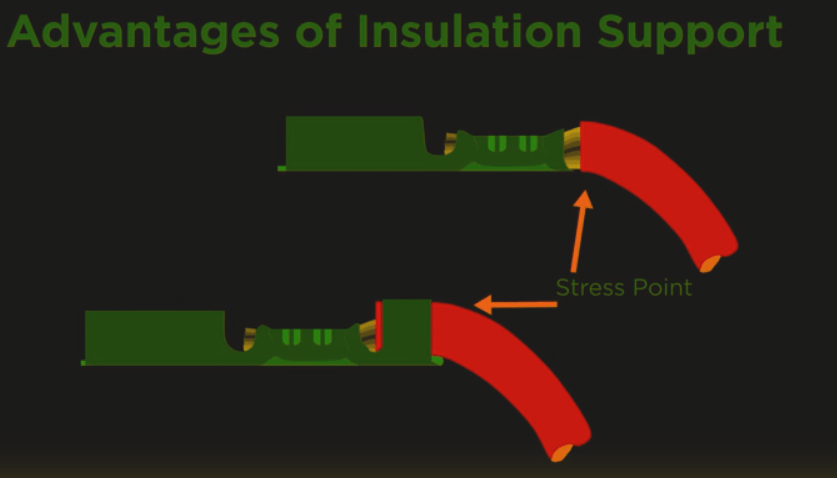

Crimp barrels, also known as wire ferrules, play a critical role in establishing reliable electrical connections. These small, tubular components are crimped onto the ends of wires to create a secure and durable bond.

Types of Crimp Barrels

- Insulated:Insulated crimp barrels provide electrical insulation and protect against short circuits.

- Non-insulated:Non-insulated crimp barrels are used when insulation is not required or when the connection is enclosed.

- Closed-end:Closed-end crimp barrels completely enclose the wire, offering maximum protection.

- Open-end:Open-end crimp barrels allow for visual inspection of the wire connection.

Choosing the Correct Crimp Barrel

Selecting the appropriate crimp barrel is essential for ensuring a secure and reliable connection. Factors to consider include:

- Wire size:The crimp barrel must match the diameter of the wire being connected.

- Insulation type:Insulated crimp barrels are required for wires with insulation.

- Application environment:Consider the temperature, moisture, and vibration levels the connection will be exposed to.

Crimping Tools: The Key to a Solid Connection

Crimping tools are specialized pliers designed to apply the necessary force to crimp crimp barrels onto wires. These tools come in various types, each suited for different applications.

Types of Crimping Tools

- Manual crimping tools:Hand-operated tools for small-scale applications and occasional use.

- Hydraulic crimping tools:Powered by hydraulic pressure, providing high crimping force for heavy-duty applications.

- Pneumatic crimping tools:Air-powered tools that offer high speed and consistency for mass production.

- Ratchet crimping tools:Ensure a secure crimp by applying a ratcheting mechanism to maintain pressure until the crimp is complete.

Using Crimping Tools

Proper crimping technique is crucial for a reliable connection. Steps include:

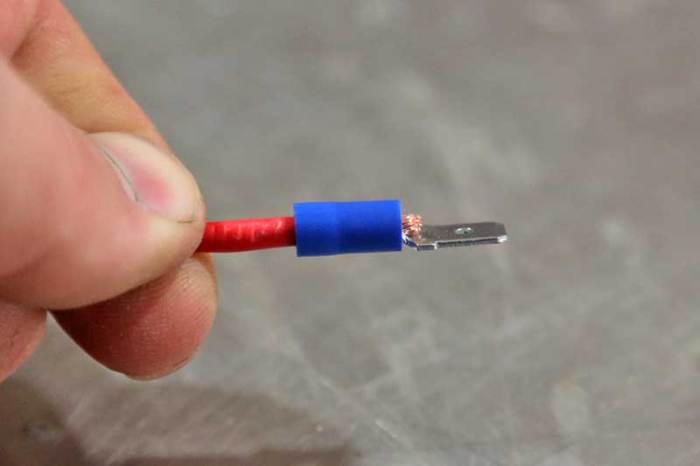

- Strip the wire:Remove the insulation from the wire to expose the bare conductor.

- Insert the wire into the crimp barrel:Place the exposed wire into the crimp barrel and ensure it reaches the stop.

- Crimp the barrel:Use the appropriate crimping tool to apply the necessary force and create a secure connection.

Crimping Techniques: Ensuring a Perfect Crimp

Mastering proper crimping techniques is essential for achieving strong and reliable electrical connections.

Common Mistakes to Avoid

- Under-crimping:Insufficient force can result in a weak connection that may fail under load.

- Over-crimping:Excessive force can damage the wire or crimp barrel, compromising the connection.

- Misaligned crimping:Incorrect alignment can cause uneven crimping and potential connection issues.

- Using the wrong crimp barrel:Choosing an incorrect crimp barrel size or type can lead to a poor connection.

Importance of Following Manufacturer’s Specifications

Adhering to the manufacturer’s recommended crimping force and technique ensures optimal performance and safety. These specifications are based on extensive testing and provide guidelines for achieving reliable connections.

Testing Crimped Connections: Ensuring Reliability, The conductor ensures a proper fit in the crimp barrel

Testing crimped connections is crucial to verify their strength and reliability. Various methods are employed to assess the quality of the connection.

Methods for Testing Crimped Connections

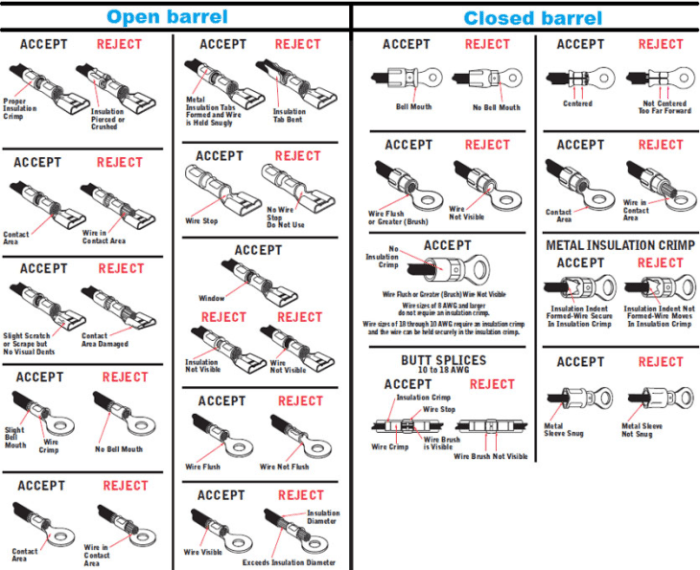

- Visual inspection:Examining the crimp for proper shape, alignment, and any visible defects.

- Pull testing:Applying force to the crimped connection to measure its tensile strength and resistance to breaking.

- Electrical testing:Measuring the electrical resistance of the connection to ensure proper conductivity.

- Environmental testing:Exposing the crimped connection to extreme temperatures, humidity, or vibration to assess its durability.

Criteria for Evaluating Crimped Connections

Crimped connections are evaluated based on:

- Strength:The ability to withstand mechanical stress and maintain a secure connection.

- Reliability:Consistent performance over time and under various operating conditions.

- Conductivity:Minimal electrical resistance to ensure efficient current flow.

- Durability:Resistance to environmental factors and long-term degradation.

FAQ Compilation

What is the purpose of a crimp barrel?

A crimp barrel is a metal tube that is crimped around the conductor and insulation to create a secure electrical connection.

What are the different types of crimp barrels?

There are various types of crimp barrels, including insulated and non-insulated, open and closed-barrel, and different sizes and shapes.

How do I choose the correct crimp barrel?

The correct crimp barrel should be selected based on the size and type of conductor, the insulation thickness, and the application requirements.